Advanced Precision Parts Manufacturing and Capabilities Overview

Table of Contents

Precision Engineering for Diverse Industry Needs #

For years, Yung Cheng Shun Industry Co., Ltd has dedicated itself to meeting the highest standards in precision parts manufacturing. Our commitment to quality is reflected in our robust production capabilities, process optimization, and meticulous control over every phase of operations—ensuring both our employees and machinery perform at their best.

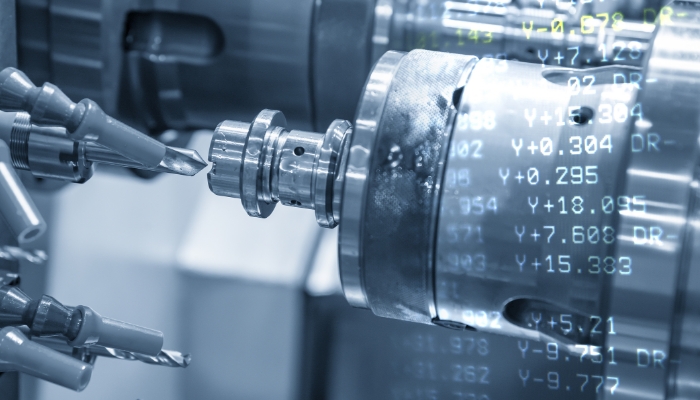

State-of-the-Art Production Equipment #

Our production lines are equipped with advanced Japanese turret-type CNC lathes, enabling us to perform turning, milling, drilling, boring, and tapping—all within a single machine. This integration streamlines precision processing and enhances efficiency.

Key Equipment and Specifications:

- CITIZEN Swiss-Type CNC Lathes: Turning diameter Ø2~Ø32mm | 34 sets

- WASINO Turret-Type CNC Lathes: Turning diameter Ø10~Ø60mm | 5 sets

- MIYANO Turret-Type CNC Lathes: Turning diameter Ø10~Ø51mm | 15 sets

- MAZAK Turret-Type CNC Lathes: Turning diameter Ø10~Ø32mm | 1 set

- NAKAMURA-WY-100 Turret Type Multitasking Machine: Turning diameter Ø10~Ø51mm | 1 set

Manufacturing Capability and Process Optimization #

Our development team is adept at matching surface treatments and machining processes to customer requirements, precision specifications, and the unique properties of various materials. This flexibility allows us to meet the needs of a wide range of parts and applications. We continually refine our processes to exceed customer expectations and foster long-term partnerships.

To further enhance our services, we have invested in:

- Japanese turret-type CNC lathes

- Composite turning and milling machines

- Automatic 3D imaging instruments

- Various precision measurement equipment

The integration of advanced CAM software has also improved our production efficiency and quality stability, ensuring reliable delivery of both products and services.

Application Areas and Industry Solutions #

Our equipment and expertise enable us to fulfill processed parts requirements across multiple industries, including:

- Remote controlled car components

- Small parts for car, motorcycle, and scooter shock absorbers

- Car braking and transmission system parts

- Medical device components

- Electronic ports and connectors

- Valve oil seals

- Automotive circuit connectors

- Connecting rods

- Disc brake and piston components

- Car steering system parts

Materials and Surface Treatments #

We specialize in processing hardware parts using materials such as stainless steel and aluminum alloy. To enhance product strength and durability, we offer a range of surface treatments, including:

- Anodizing

- Baking paint

- Anti-rust oil application

- Heat treatments

Our production line’s adoption of Japanese turret-type CNC lathes ensures that turning, milling, drilling, boring, and tapping can be completed with precision and efficiency.

If you require OEM hardware parts or have specific processing needs, we invite you to contact us for tailored solutions.

There are no articles to list here yet.