Precision Manufacturing Expertise and Company Values

Table of Contents

Commitment to Precision and Innovation #

Yung Cheng Shun Industry Co., Ltd has dedicated many years to the field of precision turning and CNC composite part processing. Our expertise encompasses CNC milling, automatic lathe processing, and the production of components widely used in industries such as bicycles, automobiles, electronics, hardware, and handheld tools.

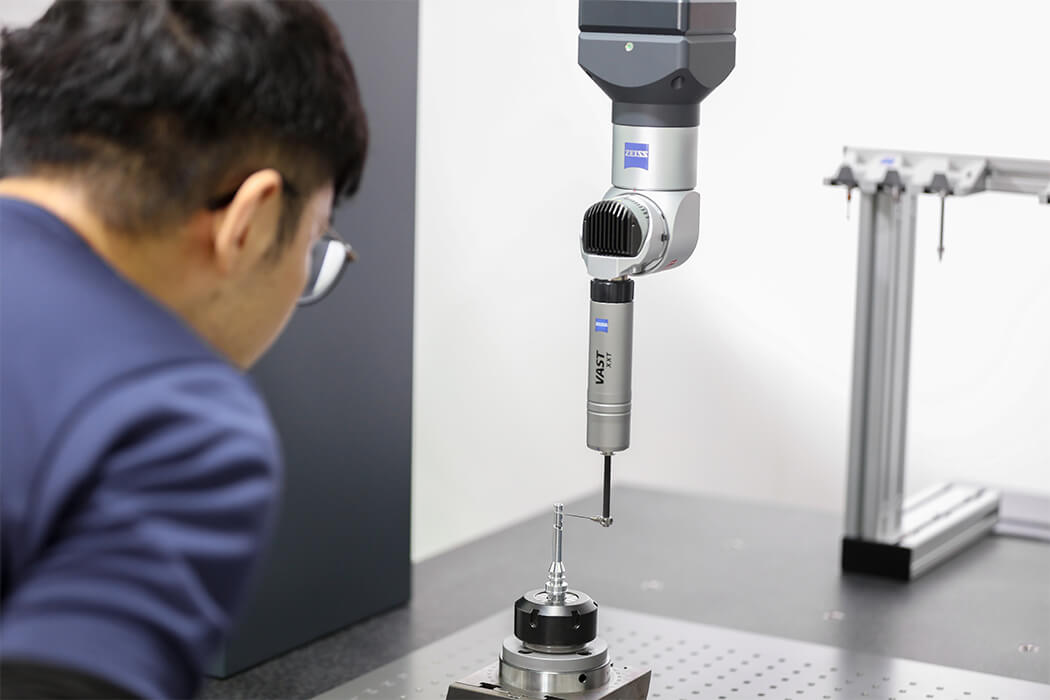

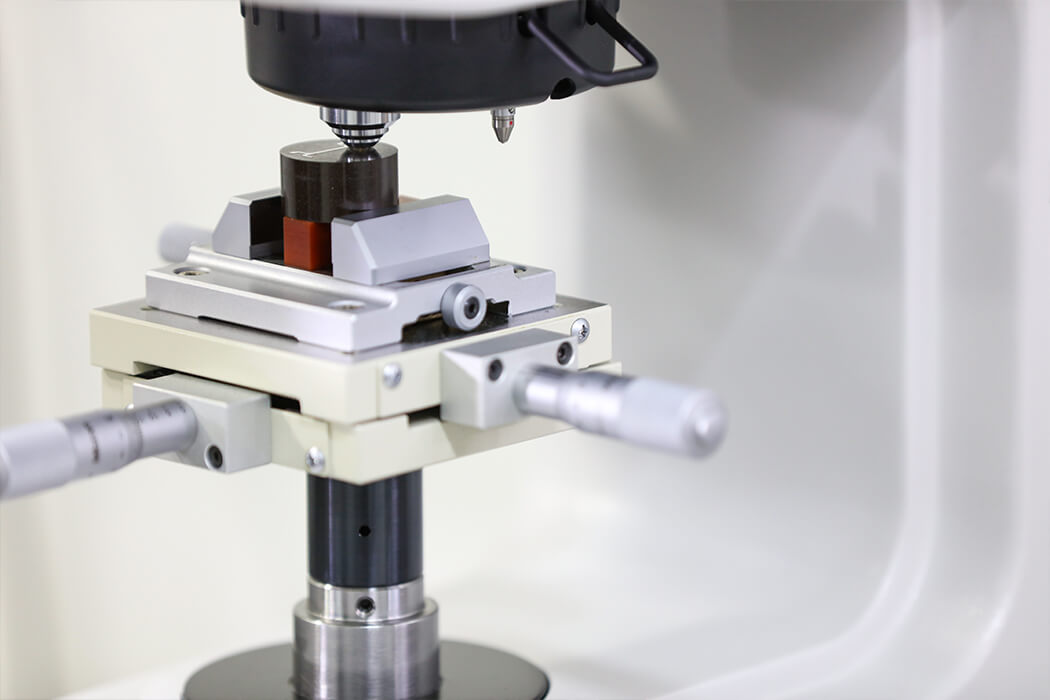

We continuously refine our production technologies to deliver comprehensive services, ensuring high quality, competitive pricing, and prompt delivery. Our investment in a diverse range of lathes and advanced precision testing instruments allows us to meet evolving customer requirements. Through a focus on research and development, as well as innovation, we consistently achieve premium results in both metallic and non-metallic part processing.

Yung Cheng Shun places strong emphasis on product quality, employee management, and ongoing training, all aimed at providing the best possible service to our customers.

Company History #

- 1987: The company was established as “Cheng Shun Industries”, primarily utilizing cam-type automatic lathes.

- 1999: Renamed to “Yung Cheng Shun Industry Co., Ltd”, the company began importing CNC automatic lathes from CITIZEN (Japan), expanded production, and constructed new facilities.

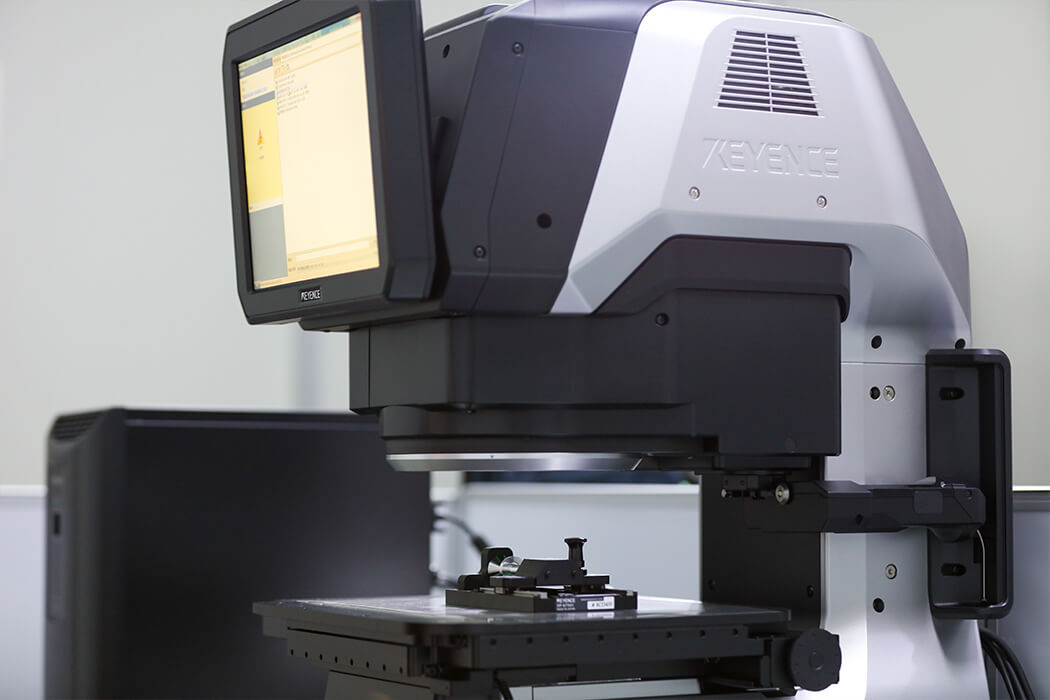

- Present: Ongoing innovation and research have led to the addition of precision projectors and other advanced test equipment. Today, our OEM processing covers a wide range of parts for hardware, electronic OA products, automotive, motorcycle, bicycle, and medical instrument sectors.

Operational Policy #

To deliver the highest standards in CNC lathe processing, turning, and milling composite products, Yung Cheng Shun has consistently upgraded its operations over the past three decades. Our goal is to grow alongside our customers and fulfill their expectations. We have made significant investments in state-of-the-art production and testing equipment, guided by principles of sustainable operation and a commitment to achieving ISO certifications. These efforts ensure that we can meet the high-precision processing demands of the future.

Quality Policy #

Customer First, Prioritize Efficiency, Top Quality

We believe that the quality of our products speaks for itself. Earning customer trust is only possible by delivering outstanding, high-quality products. To this end, we conduct quality audits throughout our facilities and among our staff. The adoption of advanced optical projectors and electronic measurement instruments, such as ZEISS coordinate measuring machines, enables us to maintain rigorous quality standards. Every phase of production is subject to diligent manufacturing tests, ensuring that all customer-commissioned parts are processed with the utmost precision and quality.